A few leftover donuts may not seem like a major problem, but for a fast-food operation with nearly 100 stores, unnecessary waste can add up to serious costs.

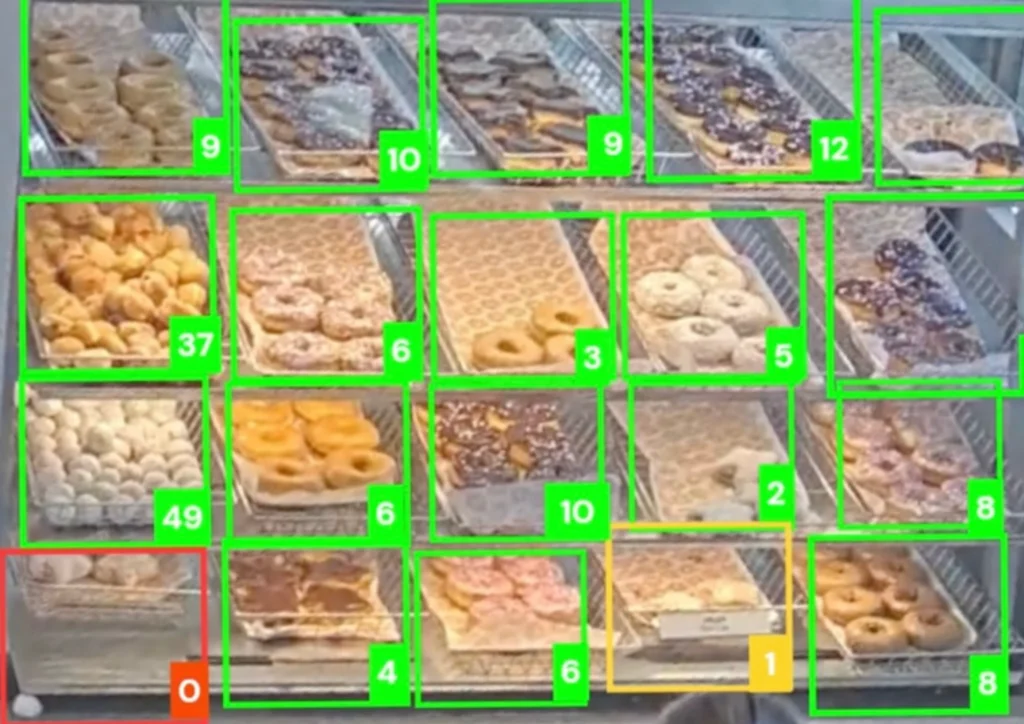

To better predict donut demand, a Knoxville, Tennessee–based Dunkin’ franchisee, Bluemont Group, has rolled out an AI system called Do’Cast designed to cut waste while keeping popular flavors in stock. Developed in partnership with restaurant AI company PreciTaste, the system uses in-store cameras to track inventory in real time and forecast demand for each type of donut. Those predictions factor in recent sales, weather, seasonal patterns, holidays, days of the week, and major local events such as college football games. So far, the companies say, Do’Cast has reduced donut and Munchkin donut hole waste by up to 25%, lowering costs while ensuring top-selling treats stay available.

“Adjusting the product mix based on what the cameras are monitoring, I think that’s one of the sweet spots for this technology,” says Moritz Illi, PreciTaste’s head of product development and lead on the Do’Cast project.

Bluemont operates about 99 Dunkin’ locations across multiple states, with donuts delivered to individual stores daily from a central bakery. Any unsold donuts are tossed at the end of the day, and before rolling out Do’Cast about seven months ago, the company saw an average of just under $100 per waste at each store per day, says Margo Hughes, Bluemont’s director of business services. That adds up to more than $3 million in discarded donuts each year, Hughes says.

“Even to cut that in half is one-and-a-half-million dollars in savings,” she says. “That’s a big deal.”

The system combines predictive modeling with image recognition, since workers in busy stores do not log each individual donut that goes out the door, particularly when customers order complex assortments. Hughes says she had read about other AI systems capable of identifying baked goods, including one used in Japan that can distinguish among hundreds of pastry varieties, and realized a similar approach could be trained to tell the difference between an Old Fashioned and a Chocolate Creme. PreciTaste, which got its start in Germany developing AI-powered oven technology that can automatically recognize different items and cook them on the correct settings, already had experience classifying baked goods.

“They had rolls, and breads, and croissants, and whatever, and these are all brown,” says Hughes. “So, I thought, surely if they can identify breads, they can identify donuts.”

The system now captures images of the donut display case several times a day so it can understand how store inventory shifts during the day and also records a definitive count of waste at the end of the day, as excess items are tossed in the trash. Having excess donuts is a waste of money, but running out of popular varieties—especially early in the day—is also a problem, and even being down to just one of a particular category isn’t ideal, since many customers are reluctant to buy the last donut, Hughes says.

“This is where the cameras are so important to assess availability throughout the day that we react quickly to non-performant algorithms based on the product mix,” Illi says.

The AI still isn’t perfect—humans at PreciTaste still supervise and validate the counts, Illi says, and store managers can communicate with the company to override the AI’s donut orders and suggest factors the system may be overlooking. It’s also still learning from new data about how different factors impact sales. Recent snowstorms led to drastically decreased demand, for instance, and changes in Dunkin’ product lineups can mean new varieties of donuts the system is unfamiliar with, so human managers may give better sales estimates for them at first.

PreciTaste, which offers ingredient prep planning for a variety of restaurant types, holds weekly calls with Bluemont to discuss how the system is performing and how it can best be tweaked. The companies also hope to incorporate other factors that can help with production planning, like understanding which donuts can serve as substitutes for each other. “If you want chocolate, you’re not going to buy strawberries,” Hughes says.

Hughes compares the process training the puppy she got around the time Bluemont rolled out the PreciTaste technology: “I know that in the long run, all the training and all the investment and all of the time is going to be worth it,” she says, “because we’re going to be best friends for life.”